White Paper:

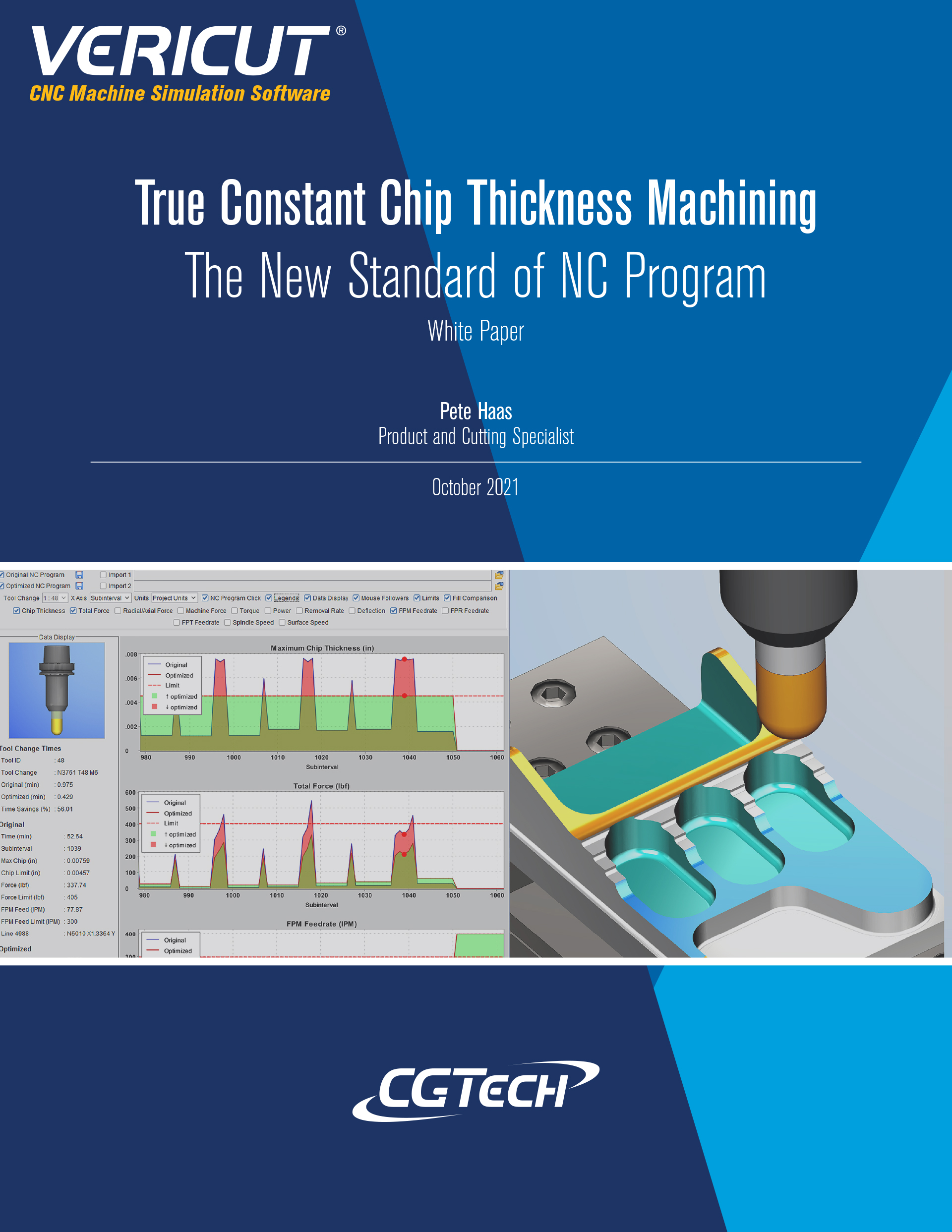

True Constant Chip Thickness Machining: The New Standard of NC Program

True Constant Chip Thickness Machining: The New Standard of NC Program

Introduction

There is a current crisis in the CNC machining (material removal) industry: cutting tools are greatly underutilizied due to less-than-optimal NC programs that do not adjust feed rates as cutting conditions change. This results in costing nearly every metal cutting company time and money. Even worse, many manufacturing companies do not even realize this inefficient cutting is happening.

The good news is that this problem presents great opportunity for substantial time savings, increased metal removal rates, improved tool life, and higher quality parts, all of which add up to substantial cost savings. This paper will describe the issue in depth, how NC simulation software reveals this problem through new graphs and data, and the solution presented in advanced NC program optimization software.

Machine tool manufacturers, cutting tool manufacturers, C-Level and manufacturing managers looking to make productivity gains should take note: this is an opportunity to make substantial productivity and profitability gains with minimal risk. Almost any shop ready for the next leap in cutting tool and machine performance improvements would benefit from this new standard of NC programs.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK Brazil

Brazil France

France China

China Japan

Japan India

India